Some good news from our friends over at Thomas.net:

Despite lingering uncertainty over potential trade wars and new tariffs on raw materials, demand for metal stamping work is still strong.

Data collected by Thomas.net shows that many metal stampers are seeing workloads that rival pre-recession levels. In fact, Thomas.net is reporting that for the last four months metal stamping companies have seen a 63% increase in production requests over its historical averages. This is exciting news for Michigan manufacturing given that nearly a third of domestic sheet metal production is located in the great lakes region.

The industry is influenced by consumption patterns in industries such as consumer appliances, telecommunications, and automotive. Over the past few years demand from the aerospace industry has remained strong and the growth of sheet metal use in other industries has counterbalanced weaker demand from common in agricultural. Most analysts are predicting that demand for metal stamping services in these fields will continue to grow in nearly all markets for the next several years with China and India seeing the most rapid growth.

While all this is great it’s important to remember that demand doesn’t necessarily translate into revenue. Threats on the horizon include increased price volatility for metals critical to the industry such as steel, aluminum, cast iron, and titanium. Other factors such as low cost overseas labor and a downturn in demand for stamped metal goods in within the oil and gas and agricultural industry will also adversely impact domestic production and prices.

The key to making the most out of upcoming trends is the same as it’s ever been: higher efficiency and higher quality.

You can check out Thomas.net’s original article here.

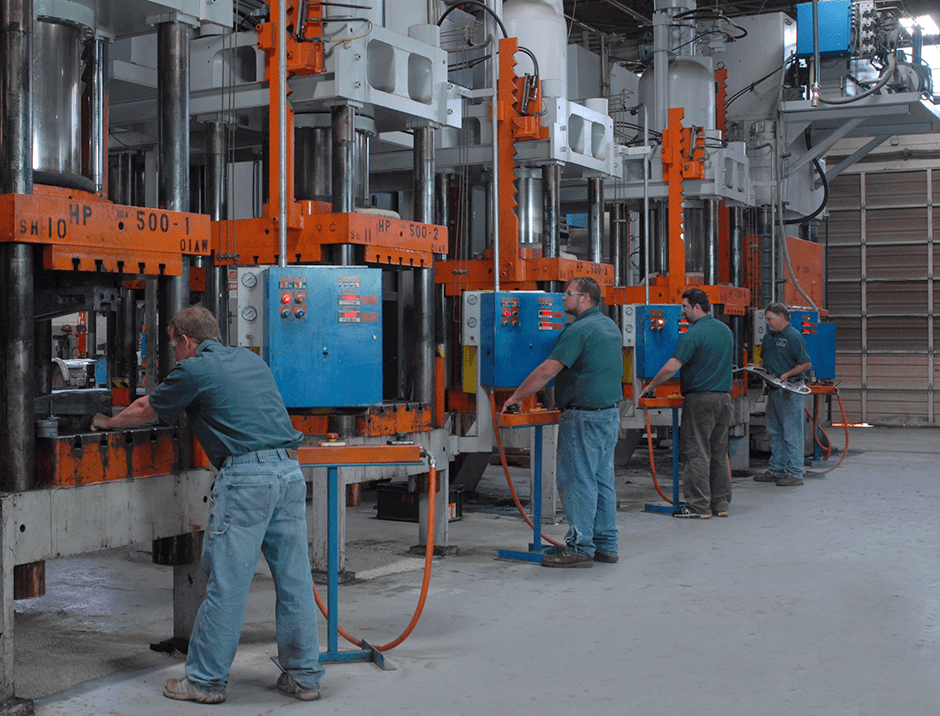

Check our Duggan’s Metal Stamping Capabilities here.