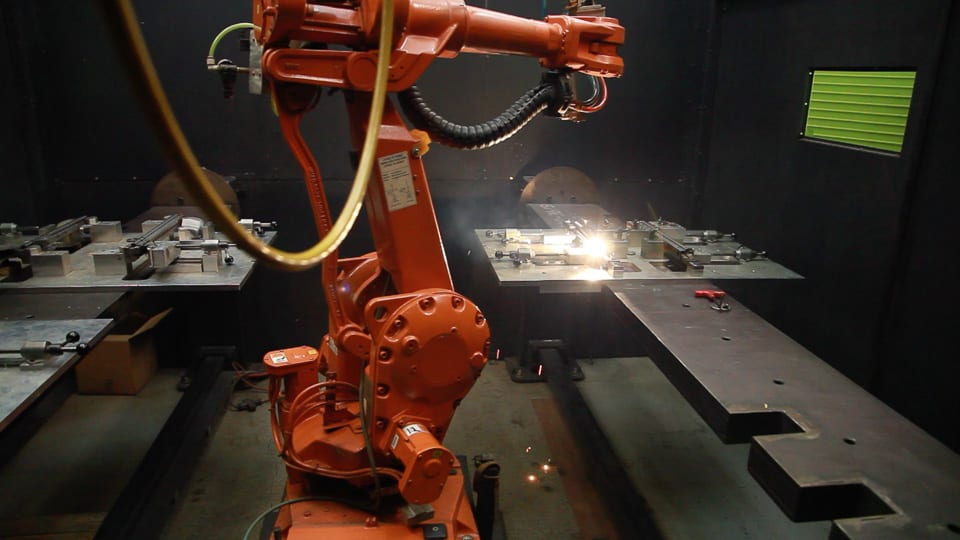

Now delivering the precision and speed of laser technology; the newest and greatest state-of-the-art robotic laser welding equipment that provides Duggan customers with performance and cost benefits not available with previous laser technologies.

At Duggan we’re proud to be a sheet metal prototype industry leader offering our customers this most up-to-date and optimally reliable equipment that more efficiently and effectively deals with a full range of metals from mild steel to zinc-coated to exotics, as well as Class “A” surfaces.

The many advantages:

Speed – Increased Throughput

Flexibility – 3-Dimensional

Material Savings – Smaller Weld Flanges plus Elimination of 2-part Epoxy

Increased Accuracies for Meticulous Fit and Finish

Improved Weld Geometries

Unlimited Weld Patterns

This exciting new robotic laser welding equipment enhances us as a total turnkey service supplier. In the hands of our professionals – with their years of welding experience, Duggan confirms once again our dedication to meeting every customer’s needs. Whatever the industry, whatever the project, whatever the timetable – this new process takes you from concept to reality to absolute satisfaction on time, on target, on budget… and laser sharp!

5-Axis Fiber Optic Laser Cutting Services

Duggan’s fiber optic laser cutting services provides our clients with:

- Better repeatability

- Fast

- Turntable increases up-time & efficiency

- Cuts reflective materials with minimal burrs

- Formed parts are typically 5-axis trimmed by a laser cutting system

- Lasers are programmed from CAD data

- Parts are checked and adjusted till in tolerance

- Up to 4 kilowatts in power

- Quicker first piece part approval

- High quality & repeatable outcomes

Laser Welding Services

Duggan was one of the first in Michigan to offer Laser Welding Services because of the many benefits.

- Minimal distortion of parts

- Stronger than other welds

- Speed–Increased throughput

- Pin-point precision

- Stampings need to be held to a greater tolerance

- Emerging technology that few company’s have the capability

- Unlimited weld patterns