Benefits and Applications

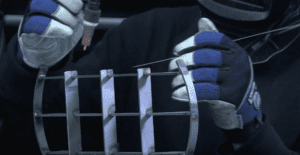

We respect our welders and know they are instrumental in the welding process. Duggan welders are certified in over 23 different types of materials and weld joints, including exotic metals.

Duggan has a library of welding procedures of many combinations of materials and weld joints certified through internal destructive testing, and 3rd party radiographic testing which prove out sound welding practices.

Duggan Manufacturing can produce numerous types of assemblies from start to finish, including full seat structures with over 100 components, window guide rail assemblies, battery boxes, turret mounts, step boxes, and airbag housings. We also offer many light assembly applications, including riveted and clinch nuts assemblies.

Capacity to Deliver

We continuously reinvest in our core capabilities, which has significantly expanded our capacity to deliver welding and assembly services to our customers. With over 30 welding machines and systems ranging from manual GTAW and GMAW fabrication cells, to automated GMAW and resistance robotic systems. We can deliver quantities of up to 100,000 parts. We also have the expertise and experience working with a range of materials including stainless steels, boron based hot stamping steels, armor, titanium, brass, copper, and aluminum.

WELDING & ASSEMBLY CAPABILITIES

| Equipment: | GMAW: 8+ Robotic; 10+ Manual. GTAW: 5 Manual. Resistance Welding: 4 Pedestal welders, 1 manual Transgun, 2 robotic servoguns. Remote Fiber Laser Welding Cell: 8kW IPG fiber laser. |

| Strength: | Sheet metal to heavy plate, joints are verified to be at least as strong as the parent material |

| Technology: | Flexible robot cells with positioners and fixturing to meet any need |

| Part Sizes: | .25 inch to 40 feet. Sizes are limitless in manual arc welding applications. |

| Materials: | Stainless Steel, Boron Based Hot Stamping grades, High Strength Low Alloy, Domex, Armor, Galvanized Steel, Hot and Cold Rolled Steel, Spring Steel, Aluminum, Titanium, Copper, Brass |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D |

| Capacity: | 1-100,000 parts annually: Prototype, Short Run, Low Volume Production |

| Additional Specialization: | Resistance and Remote Laser Welding |

How We Do It Better

To provide quality welding and assembly services offered at Duggan Manufacturing, we employ American Welding Society Certified Welding Inspectors (AWS CWI). What this means to our customers is that we provide standards of quality on par with the best in the nation.

Duggan has an ISO 17025 accredited metallography laboratory that performs cut and etch tests (cross-sections of welds measured under a calibrated microscope), tensile, compression, torque, and bend tests to verify our products meet all your requirements.

Gas Metal Arc Welding (GMAW/MIG)

| Equipment: | Robotic and semi-automatic welding stations equipped with standard Constant Voltage or pulse-capable welding power sources |

| Strength: | Parts from sheet metal to heavy weldments can be joined, with resulting joints being at least as strong as parent material |

| Technology: | Flexible automation cells with positioners and fixturing to meet any need |

| Part Sizes: | Duggan has floor space to accommodate projects of almost any size |

| Materials: | Stainless Steel, Boron Based Hot Stamping grades, High Strength Low Alloy, Domex, Armor, Galvanized Steel, Hot and Cold Rolled Steel, Spring Steel, Aluminum, Titanium, Copper, Brass |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D |

| Capacity: | 1-100,000 parts annually: Prototype, Short Run, Low Volume Production |

Gas Metal Arc Welding (GMAW/MIG)

Gas metal arc welding is a welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together while protected by an inert or active shielding gas

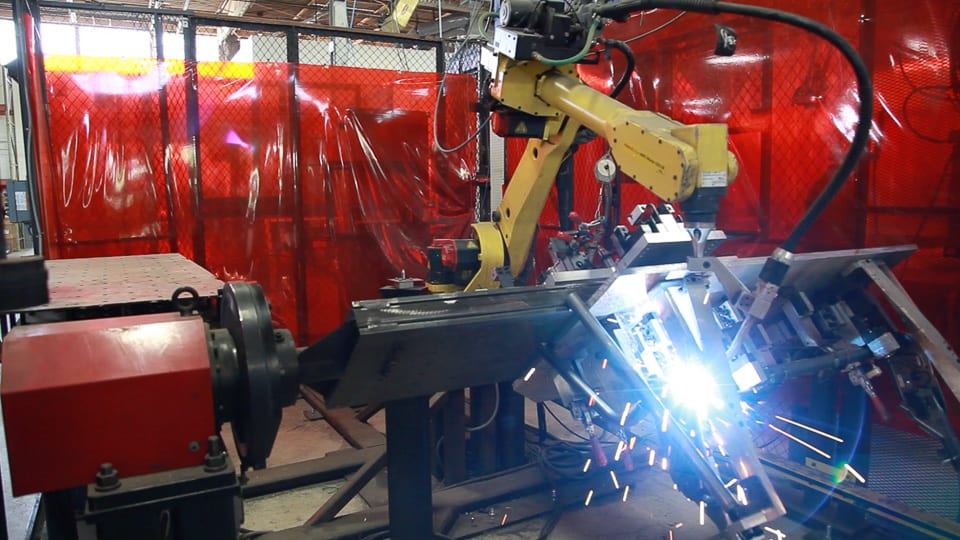

We offer both manual and robotic GMAW welding. Robotic welds excel in speed and repeatability for short run or low volume production work on sheet metal and simple parts.

Manual GMAW is used for more complex fabrications or large assemblies, and Duggan carries a library of tested and certified Welding Procedure Specifications (WPS). What this means is that we have tried and true, certified settings and procedures.

Gas Tungsten Arc WELDING (GTAW/TIG)

| Equipment: | 5 Miller Dynasty or Synchrowave power sources |

| Strength: | Ability to weld parts with material thicknesses from foil and sheet metal to thinner plate sections, including exotic alloys and materials |

| Part Sizes: | Duggan can accommodate parts of most any size |

| Materials: | Stainless Steel, Boron based Hot Stamping grades, High strength low Alloy, Domex, Armor, Galvanized Steel, hot and Cold Rolled Steel, Spring steel, Aluminum, Titanium, Copper, Brass |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D |

| Capacity: | Prototype, Short Run |

| Additional Specialization: | Aerospace grade metal-finished parts |

Gas Tungsten Arc WELDING (GTAW/TIG)

GTAW is a welding process which uses a non-consumable tungsten electrode to create a weld puddle, and a separate filler metal rod inserted into the puddle to fuse base metals together. GTAW welding is typically a manual process used for exotic materials like aluminum and stainless steel, or for tight tolerance sheet metal fabrication.

MIG WELDING

| Equipment: | Over ten robotic MIG capable units equipped with fronius or pulse welding and traditional capabilities. 12 manual welders certified to weld most products |

| Strength: | Parts as thick as 2″ can be joined. Bonds are as strong as the tensile strength of the parent material. |

| Technology: | Programmable robotic weld patterns utilizing Fanuc controls and Miller power units |

| Part Sizes: | .25 inch to 40 feet. Sizes are limitless in manual applications |

| Materials: | Stainless Steel, Boron Based Hot Stamping grades, High Strength Low Alloy, Domex, Armor, Galvanized Steel, Hot and Cold Rolled Steel, Spring Steel, Aluminum, Titanium, Copper, Brass |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D, ISO/IEC 17025 |

| Capacity: | 1-100,000 parts annually: Prototype, Short Run, Low Volume Production |

| Additional Specialization: | Laser welding |

MIG Welding

MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination.

We offer both manual or hand welding and robotic MIG welding. Robotically, MIG welding offers precision as well as accuracy, and increases efficiency and speed, which is necessary for short run production or low volume production work.

Manual or hand MIG and can begin in as little as a day or two, with high confidence, because we carry a full library of WPS (weld procedure specifications). What this means is that we have tried and true, certified settings and procedures.

TIG WELDING

| Equipment: | 5 manual |

| Strength: | Ability to weld parts with material thickness from .25mm to 12.77 mm including exotic super alloys |

| Part Sizes: | Parts as thick as 2″ can be joined. Bonds are as strong as the tensile strength of the parent material. |

| Materials: | Stainless Steel, Boron based Hot Stamping grades, High strength low Alloy, Domex, Armor, Galvanized Steel, hot and Cold Rolled Steel, Spring steel, Aluminum, Titanium, Copper, Brass |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D, ISO/IEC 17025 |

| Capacity: | Prototype, Short Run |

| Additional Specialization: | Laser welding |

TIG Welding

TIG welding is a similar process to MIG welding. Instead of a continuous wire feed, a long welding rod is utilized for the weld. TIG welding is typically a manual process used for exotic materials like aluminum or tight tolerance sheet metal fabrication. TIG welding is based on skill. TIG or MIG, the welders at Duggan have the ability to weld a thin aluminum can up to a thick armor plate.

RESISTANCE WELDING

| Equipment: | AC/DC powered units Trans gun for bigger parts |

| Strength: | Ability to weld 3 and 4 material welds with part thicknesses from .25mm to 6.35mm thick |

| Technology: | Beam can be split to weld multiple work pieces simultaneously |

| Part Sizes: | .25 inch to 9 feet |

| Materials: | Stainless Steel, Boron Based Hot Stamping Grades, High Strength Low Alloy, Domex, Armor, Galvanized Steel, Hot and Cold Rolled Steel, Spring Steel, Aluminum, Titanium |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D, ISO/IEC 17025 |

| Capacity: | 1-100,000 parts annually: Prototype, Short Run, Low Volume Production |

Resistance Welding

Commonly known as spot welding, resistance welding is used to join two or more sheet metals together using applied pressure and heat from electrical current to “forge” materials into a welded nugget. It is also used to weld projection fasteners and components together. It is a very quick, efficient process, with welds tested quickly by peel, torque, or shear tests.

Over time, as customer demand has grown for resistance welding, we have expanded our capacity and welding capabilities. We have multiple AC pedestal units and a DC unit capable of welding a variety of materials and thicknesses on lower volume production. For large spot weld patterns, we have a transgun that can maneuver over a 14 foot span which allows large workpieces to remain stationary while welds are added to it. Recently we have also added two Fanuc robots with servoguns for automotive or higher volume production work.

REMOTE LASER WELDING

| Equipment: | IPG fiber laser. Precitec head that senses dissentious patterns and adjusts to match actual part changes. |

| Strength: | 8 KW of power with the ability to clad material |

| Technology: | Beam can be split to weld multiple work pieces simultaneously |

| Part Sizes: | .25 inch to 10 feet |

| Materials: | Stainless Steel, Boron Based Hot Stamping Grades, High Strength Low Alloy, Domex, Armor, Galvanized Steel, Hot and Cold Rolled Steel, Spring steel, Titanium |

| Certifications: | ISO 9001:2015, IATF 16949:2016, AS9100-D |

| Capacity: | 1-1,000,000 parts annually: Prototype, Short Run, Low Volume Production |

Remote Laser Welding

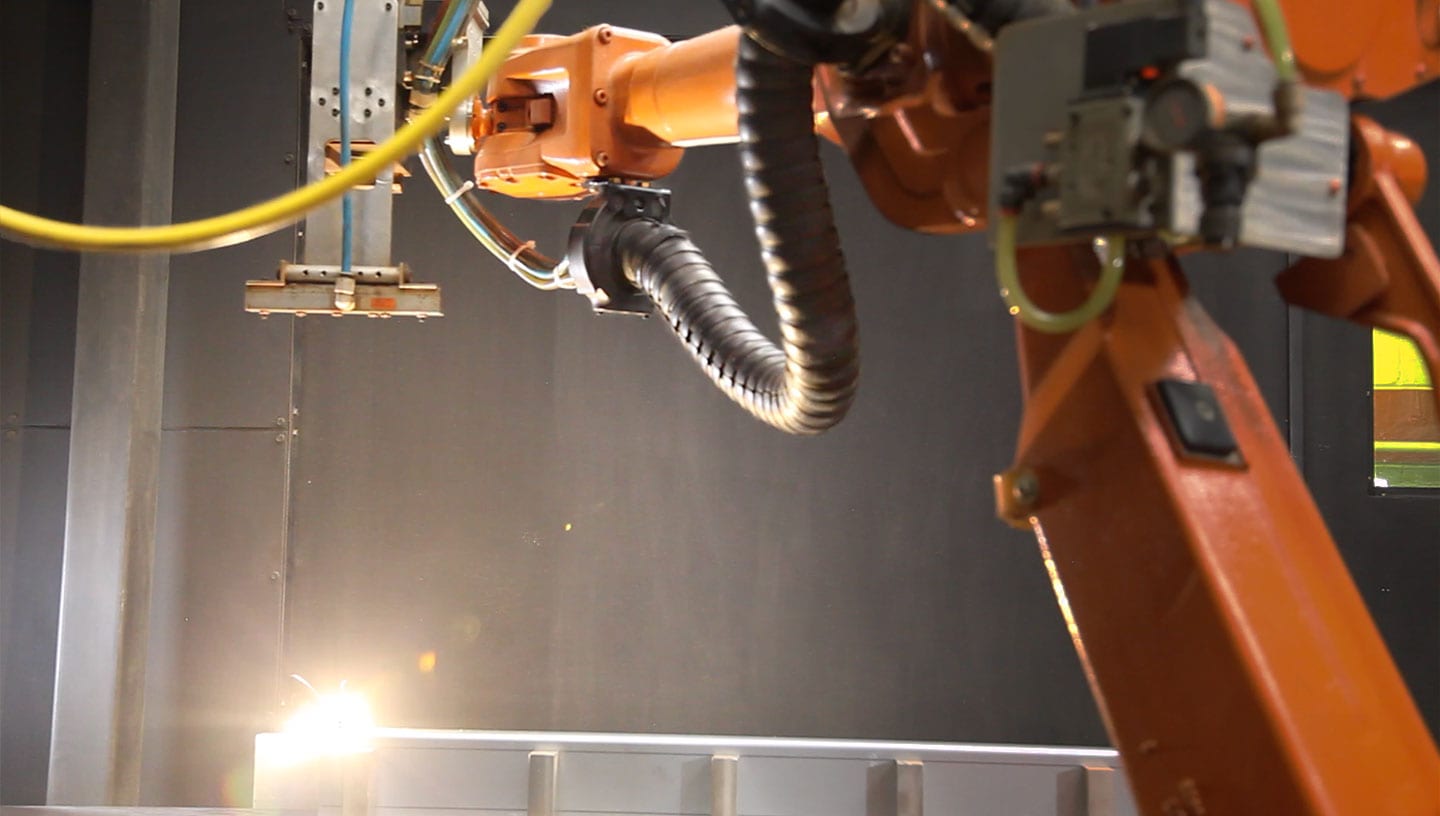

Duggan Manufacturing offers remote laser welding. This is a specialized process of welding which uses excited energy directed through a fiber optic tube to fuse metals together without applying filler metal. The weld produced from the laser is typically stronger than the parent material.

Without filler metal, laser welding aids in producing lightweight assemblies with very little part distortion, and in most cases the part tolerances are intact after the welding process. This comes from the high energy density and high depth to width ratio inherent with laser welding, which produces very narrow Heat-Affected Zones (HAZ) prominent with other welding processes. High speed is another advantage of laser welding, which further increases productivity and decreases distortion, welding up to 120 welds per minute at rates of 100-200 inches per minute.

Materials We Work With:

- Stainless Steel

- Boron Based Hot Stamping Grades

- High Strength Low Alloy

- Domex

- Armor

- Galvanized Steel

- Hot and Cold Rolled Steel

- Spring Steel

- Aluminum

- Titanium

- Copper

- Brass

Certifications:

You can find a full list of all of our certifications here.